Advantages

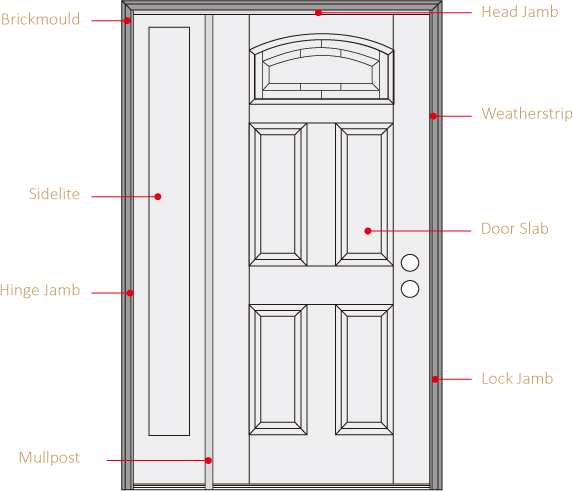

LastnFrame™ composite door frame components are a mixture of PVC and wood fiber composite substrate. Maintenance-free smooth white or woodgrain composite offers all the strength and stability of wood, providing a moisture and damage resistant solution engineered to work together with doors and components.

Performance

• Twice the holding power of wood

• Will not discolor, absorb moisture, wrap, split or rot

• Resists mold, mildew, fungus, insects, salt and chemicals

• Can be easily nailed and machined

Features

• No sanding or priming required, ready to finish

• Composite jambs are ready to install, no finishing required

• Textured woodgrain composite components complement rich wood appearance

• Composite jambs can be painted or stained to requirements

LastnFrame™ composite door frame components featuring an innovative an innovative alternative to traditional wood frame construction.

Composite technology provides a rot-free solution engineered to work together with

rot-resistant doors and components

Composite Door Frame Kits

• Moisture and insect resistant

• Will not rot, split, twit or warp, maintenance-free

• Stronger than wood jambs

• Can be routed and cut without chip outs

• Can be fastened close edges

Weatherstrip

• Kerf-applied to fit securely into the top and side jambs

• Flexible, foam-filled material holds its shap over time

• Traditional .650” reach ensures a weather tight seal

Bottom Sweep

• Kerf Applied

• Multiple fins help block moisture infiltration and deflect moisture away from the cap

• Available in Dark Brown Color

Corner Seal Pad

• Wedge shaped adhesive-backed

• Will not wick water. Apply to corner of jamb

• Mate with inswing sills to complement weathersealing performance